WHY USE SSMD REVERSE ENGINEERING SERVICES?

20+years of experience.

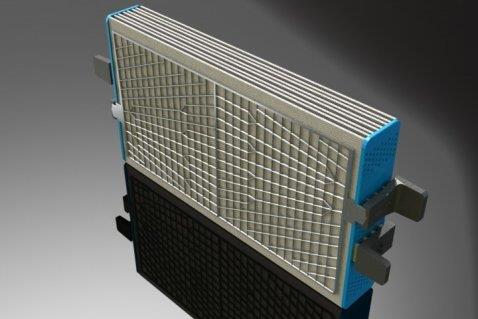

We give you all the 3D models and fully dimensioned drawings.

We save you money and time.

According to the calculations with our current clients, we have found the average savings is now more than 2/3 the OEM price! This means, on average, a part that costs $1000 from the original manufacturer will cost less than $300 after we replicate it. Delivery times from local manufacturers are dramatically improved as well – from 12 weeks down to as little as 2 weeks (depending on the part) – without a rush order! This is a big advantage for companies looking to reduce costs from their current methods of part replacement.

You could save 30, 40, 50% and more over OEM prices!

Original Equipment Manufacturers (OEM’s) are supplying parts at exorbitant rates and many OEM’s have gone out of business and are no longer able to supply your parts. Rather than repeating an OEM with a single machine shop, SSMD will create 3D models and fully dimensioned drawings of your spare parts that you own forever! Those drawings can be submitted to several machine shops for quotation and your parts can be manufactured by American made machine shops at a reduced cost.

Average Price VS OEM Parts

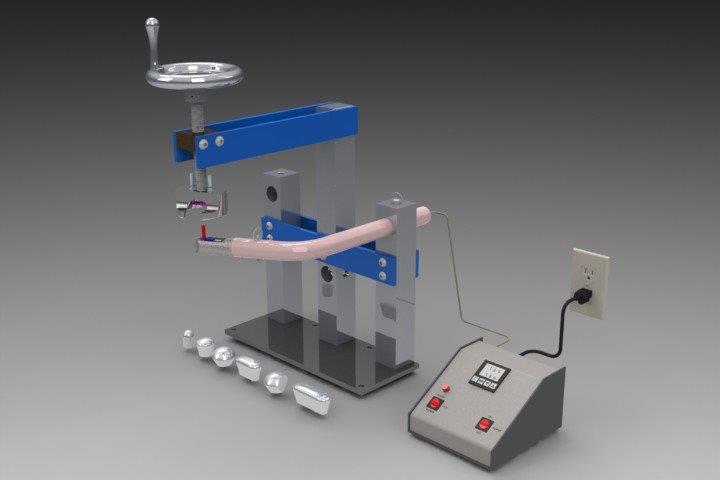

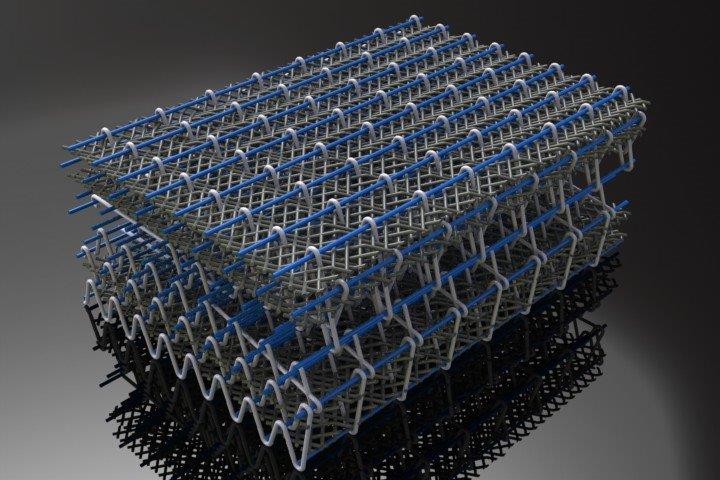

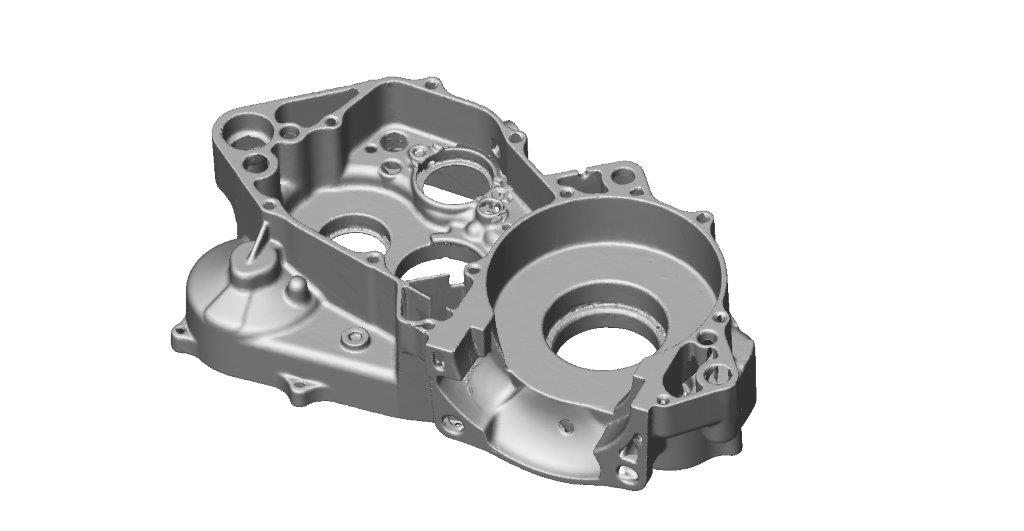

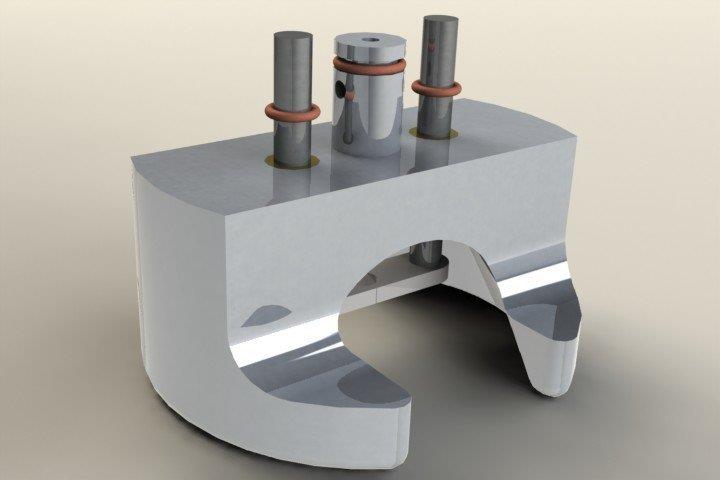

SSMD has been Reverse Engineering machine components for over 20 years and every client has received fully dimensioned drawings on every part that we have ever made for them. Items such as gears, levers, arms and mounts, or virtually any part that has a tendency to wear out or break can be reverse engineered by SSMD. SSMD will replicate the part including materials, tolerances, hardness, and finish. Even if you don’t use our part procurement services, you still own the drawing.

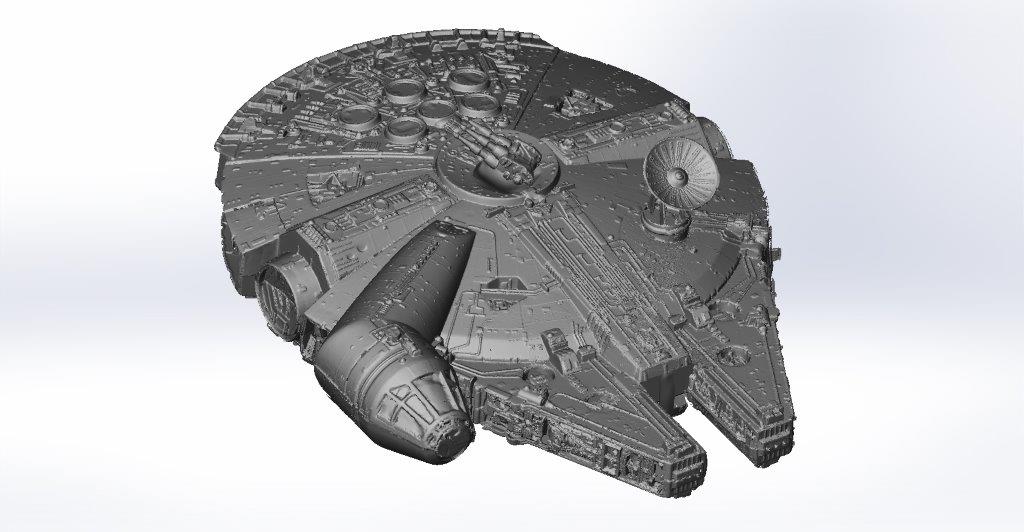

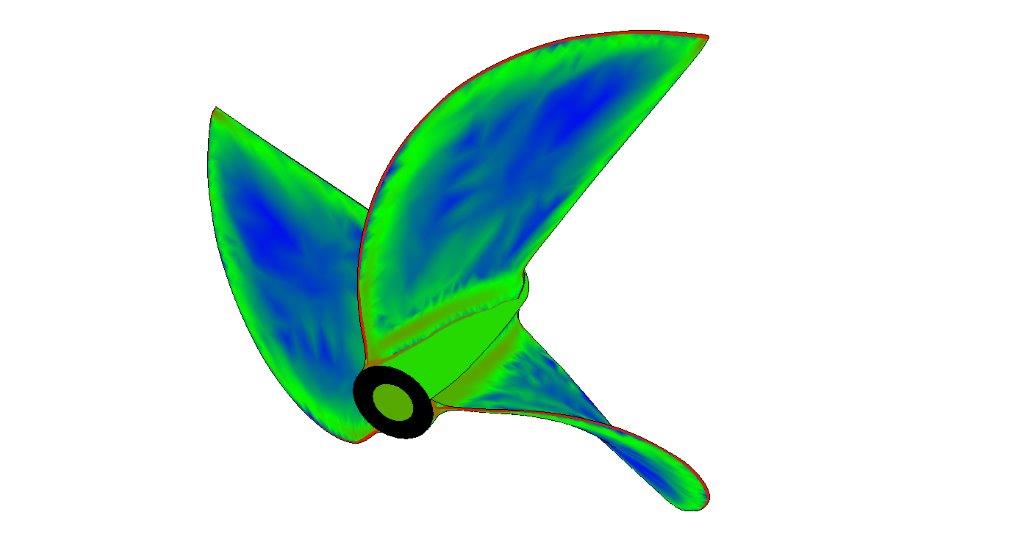

SSMD uses a full array of standard metrology equipment and a 7-axis 9’ Faro Edge with HD Laser Scanner to replicate strange shaped items such as cams, propellers, and free-form shapes (see the ever changing gallery of laser scanned items). SSMD uses powerful GeoMagic DesignX software to transfer massive point clouds into 3D surfaces and models. This information is transferred into CAD by our SolidWorks Certified Professionals to create drawings and transferrable 3D models for machining purposes.